APPLICATIONS OF FIBRES

The textile industries are developing at a rapid rate

with the manufacture of different types and different functional textiles. This

chapter deals with the identification of fibers and indicates various. Applications

of textile materials.

IDENTIFICATION OF TEXTILE FIBRES

Fibers broadly can be classified into organic and

inorganic types. However, most of the fiber-forming polymers are of organic

origin. They may also be either thermoplastic or thermosetting in nature which

determines

their solubility and fusibility behaviors. Due to their

organic nature most of the polymers are inflammable and during the burning show

specific characteristics depending upon the nature of the polymer. Fibers or

polymers owe their specific properties to their unusual large molecular size,

consisting of small repeating units.

Owing to this they resemble lower molecular weight

compounds and reactivity of the functional groups remain unchanged in polymers.

So the polymers can be identified by normal functional group analysis. Thus,

identification of polymers is possible by their burning characteristics aided

by elemental analysis and solubility behavior. This approach is inexpensive,

simple and requires very little time. Once the nature of the polymer is known,

then further characterization is possible by more sophisticated methods.

There are different types of tests to identify the

textile fibers. The different tests can be summarized as:

Tests Non-technical tests Technical tests

- Feeling test Microscope test

- Burning test Density measurement

- Staining test Chemical test

FEELING TEST

Different fibres show different behavior when you will

place your hand on them. Details of the feeling test are mentioned in Table Feeling

Characteristics of the Fibres Cool to touch feels soft and inelastic Cool to touch,

feels smooth and leathery Cool to touch, feels smooth and leathery Warm to

touch feels elastic and smooth Warm to touch, feels elastic and springy Cool

to touch feels smooth, inelastic and lustrous Cotton Linen Jute Silk Wool

Rayon more elastic and resilient

Different fibres show different behavior when you will place your hand on them. Details of the feeling test are mentioned in Table Feeling

Different fibres show different behavior when you will place your hand on them. Details of the feeling test are mentioned in Table Feeling

Characteristics of the Fibres

- Cotton - Cool to touch, feels soft and inelastic

- Linen - Cool to touch, feels smooth and leathery

- Jute - Cool to touch, feels smooth and leathery

- Silk - Warm to touch, feels elastic and smooth

- Wool - Warm to touch, feels elastic and springy

- Rayon - Cool to touch, feels smooth, inelastic and lustrous

- Acetate Nylon - Little warm to touch, feels smoother, more elastic

and resilient than rayon

- Nylon - Feels very smooth, lightweight, elastic, lustrous

- Polyester - Feels very smooth and stiffer

- Acrylic - Feels like wool, but lightweight and slippery feeling

- Polypropylene - Extremely lightweight, resilient smooth and lustrous

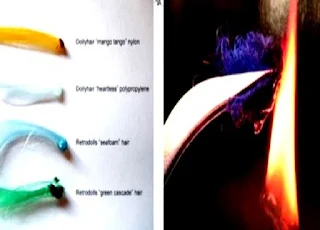

BURNING TEST

To identify the fibres by burning the test, the sample

should be moved slowly towards a small luminous flame. The burning rate and

burning characteristics, after it is removed from the flame, should be noted.

The fibres can be identified by the observations mentioned in Table

Burning Characteristics of Fibres

Cellulosic Fibres Cotton, Jute Flax, Viscose

Burns with little ash and yellow flame, odor similar

to that of burned paper.

Wool

Burns slowly with slight sizzle and ceases flaming when

the fire is withdrawn. The color of the flame is yellow-orange with blue or

purple bottom edges. The ash is dark and crisp. It can be crushed easily with

fingers. The odor is like burning human hair or feather.

silk

Burns readily with light sizzle. The flame is orange-yellow color and blue-grey smoke. The flame sparkles, the fiber swells, and

chars. The odor is like burning human hair.

Casein

On exposure to flame, the fibre swells, burns, and chars

with yellow color and grey smoke. The odor is like burning the milk.

Acetate fibre

The sample fuses with yellow, mauve or blue-base

color melts into a hard mass. Acetate Fibres The ash is hard and brittle and it is difficult to crush odor is like that of vinegar. between the fingers.

Nylon

The sample fuses and shrinks away from the flame burns

slowly with the yellow, orange or blue bottom with melting. Forms round, furnish brittle, hard black bead. On melting the odor will fresh celery burning

vegetation.

Polyester

The fibre softens, melts with a yellow-orange color and

black smoke with sweet aromatic odor and shrinks away from the flame. Forms

irregular hard bead.

Polyester

The sample fuses and shrinks away from flame melts,

burns vigorously leadıng a hard, dark brittle residue.

Acrylic

Will not burn, ignited giving negligible color or

yellow sodium flame in case of Glass A fibers. Glass