TWISTING

Twisting is one of the main process carried out for man-made

fibers twisting induces the following advantages properties

(a) Increase in density and compactness

(b) Better appearance

(c) Higher breaking strength

(d) Imparting certain

properties like rigidity, flexibility, etc.

(e) improved resistance to

bending and wear

(f) Better processing

capacity

Type of twisted yarn

Twisted yams are generally

classified into three groups, as per the yam twisted. These will be

(i) low-twist yarn having

maximum of 230 twists per meter,

(ii) medium-twist yarn

having 230 to 900 twists per meter and

(iii) Hard twist yarn having

more than 900 twists per meter.

Type of twisting

The twists may be 'Z' twist

or 'S' twist as per the direction of the twists impart. Twisted yarns are

generally used in the following areas:

(i) in weaving and knitting,

(ii) For industrial purpose like ropes,

cable, cords, nets, etc,

(iii) For consumer goods like sewing threads,

embroidering twines etc.

The man-made fibers are

generally twisted in two stages. All the fiber plants performed the stretching

or drawing operation in a draw twisting machine. So a low twist is generally

applied to the parallel filaments in stretching operations. After this

operation, the filaments are delivered to the twisting department where medium

twisted and hard twist yams along with another type of twisted yarns are produced.

Type of twisting machine

The twisting can be done in any of the following machines.

(a) Ring twister

(b) Ringless twister

(c) Two for one twister

(c) Two for one twister

In-ring and ringless twister, the spindle may be single-twist spindles. Single process two-zone twisters are used to produce industrial twisted yams like tire cord.

RING TWISTING

The operation of

ring-twister is similar to that of the ring spinning. Ring-spinning is used

to perform drafting, twisting and winding whereas a ring-twister will perform

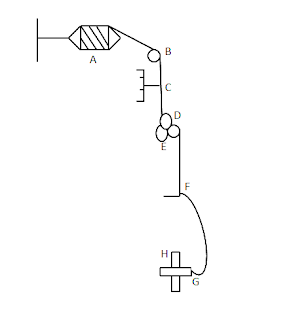

only twisting and winding. The principle of the operation is shown in Figure.

The supply package is placed

on the creel (a). The thread unwinds from the supply package, deflected its

motion by means of the guide rod (b), passes through the guide hook (c) and

enters the feeding device.

The feeding device generally

consists of three rollers connected with each other to grip the yan (d,e).

These three rollers consist of two cylinders and top rollers. From the feed

roller, the yarns pass through the guide hook (f), through the traveler (g)

and wound on the bobbin (h) placed on the spindle (i). Twisting is done by the

movement of the traveler and gripping of the feed roller.

Each revolution of the

traveler gives one twist to the yam, which is transferred up to the nipping

point. The total no. of twists depends upon the traveler speed or the

revolution. The exact amount of twist per cm is the ratio of the traveler

speed in rpm divided by the surface speed of the feed roller.

RINGLESS TWISTING

the principle to twist filaments by ringless twister is

similar in principle as that of the roving. In both cases a flyer is used

to collect the filament I instead of a ring and traveler. It is used only for

hard twists. The flyer may also be used for the supply package. The flow diagram of

a ringless twister or deck twister is shown in Fig

The supply package is fitted

on the spindle. The thread coming out from the supply package passes through

the edge of the flyer on the thread guide. The yarn passes from the thread

guide to an antiballooner guide and from it to the take-up bobbin through the

traverse guide.

The yarn comes from the supply package, fitted as a rotating spindle. So each rotation, the yarn will be twisted for one turn in the section between the supply package and the antiballooner.

The yarn comes from the supply package, fitted as a rotating spindle. So each rotation, the yarn will be twisted for one turn in the section between the supply package and the antiballooner.

TWO FOR ONE TWISTER

The efficiency of the

existing twisters can be considerably increased by using double-twist

principle. The general principle of this method is shown

Processing of fiber In an

ordinary twisting machine, one revolution of the spindle imparts one twist to

the yarn. So the number of twists per unit time is limited by the spindle speed

and the yam velocity. The maximum spindle speed is always restricted to 15,000

rpm. So the yarn velocity will be restricted to 60 m/min for a medium twist

yarn having 250 turns per meter. The twister is modified with a double twist

spindle. This ensures two twists per one revolution of the spindle. The system

increases the production rate.

The yarn is withdrawn from

the supply package through a yarm guide. The supply package is placed stationary on a hollow rotating

spindle.

The yarn moves downward

through the yarn guide to the hollow spindle. Further, it moves upward through a

yam outlet hole to the yarn take-up roller and then to the winding head. A

balloon separator is placed to avoid any

entanglement and frictional contact between the stationarý package and the

yarm.

The yarn coming out from the

package passes through the tension roller traverse guide and collected in the bobbin. Each revolution

of the spindle inserts one twist into the yam moving downward and another twist

into the yarn moving upward.

So simultaneously one

spindle revolution inserts two twists into the yam in the same direction. The

machine operates at a speed in the range of 10,000 rpm to 14,000 rpm with a

package weight of 3 kg. Each revolution inserts two tuns of twist and the

method of twist insertion does not involve high-speed rotation of the package.

So the machine has a relatively low power consumption.